Well in so many words , just like you did on the top . Your distance though is going to be measured from the side of the RR channel up to either the line you just drew, if you want a V or to a distance below the line if your after more of a U belly.

Keep in mind , this shaping does not carry all the way to the nose cap .

your nose cap design defines the top of the forestock down to about mid point of the cap . The cap also defines the shape of the stock for a distance behind the cap.

Depending on the rifle im building , I carry the nose cap shape back at least an inch some times an inch and a half before I transition into the shaping to the RR channel

The pre carve stock for your rifle appears to have a very thick web between the barrel and the RR channel . As such you need to plan on shapes and molding that will help give the perception of length, and slimness if your wanting a slim rifle . If your shooting for a more heavy frame then you look at shapes and molding that do the opposite.

So at this point my recommendation would be to shape the stock , behind the nose cap , for a short distance , to the shape of your nose cap . This will help start the impression of slimness and give the impression of length. DON’T go to far back , keep at least a ½ inch in front of your front barrel pin .

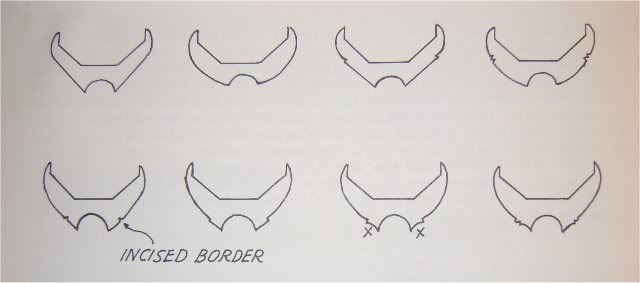

Here are also some different fore stock shapes for you to consider . While you looking at these consider your moldings and how they will relate to your shape . IE will they be deep and in heavy or light relief . ?

Will they be just incise lines .?

Will you have a double row so that the shaping will come around from the barrel , drop into an incise line , then into a concave molding , back to incise then around to the edge of the RR channel?

Maybe you might want no moldings with just a nice S sweep coming off the barrel down and out to the RR channel . Its really up to you . But you have to plan this out . Some molding work takes more wood others take less .