Many years ago we had a sticky on this subject . Must have been lost in that big clean up we had .

I still have some of the photos that I did concerning this so ill try to do a condensed explanation.

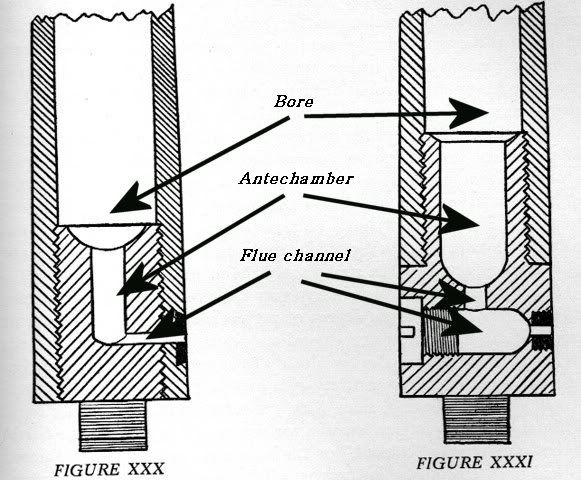

The original patent and improved breech plug designs art really anything close to what pedersoli or TC uses . Bothe the design of Nock and Manton had small flue’s that lead to an Antechamber . While these are later drawing , you can get the idea .

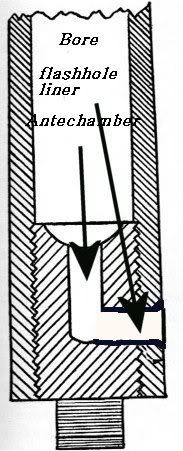

What pedersoli uses is a modification on the design in that they did away with the Flue and basically made the Antechamber a dog leg . Here is a drawing of the pedersoli plug

Now as to they why of it .

Well as others have said , it is supposed to give a increase in ignition speed .

However remember that the “ORIGNINAL “designs came about during a time when every well known maker was trying to come up with anything they could which they could claim would increase the speed and reliability of the flintlock ignition .

It also provides for a stronger breeching as it allows for far more threads then a standard type breech

They Antechamber also , acted like a booster to the main charge . To understand that , we have to realize what happens during the micro second of the powder burn and the resulting pressure wave that started as the first grain of powder ignites.

In doing so we then understand that the Antechamber provides a much smaller area of burn . Directs that initial pressure and heat wave forward into the rear of the main charge .

The resulting back pressure “concerning a flintlock application “ then makes the small flue’s pretty much self cleaning . They end up acting much like a nozzle on a hose and produces a very strong jet out the flash hole . So strong in fact that its not uncommon to see originals that have pans showing signs of gas cutting . Some later makers even went to the point of making a small notch in the outside edge of the pan . These often also had a corresponding tab on bottom of the frizzen .

Now lets jump forwards in time , where this breech design was applied to the cap lock .

When this was done , for the most part the flue’s were done away with . You also see the advent of the Improved breech which incorporates the bolster as part of the breech . Thus producing a stronger design when compared to the earlier drum type bolster .

The problem however is that because of this larger Antechamber you don’t get as much nozzle effect which results in a build up of carbonized fouling throughout the entire system . If this isn’t cleaned regularly the fouling will build tell it reaches a point where the resulting back pressure is sufficient to maintain only a small channel through the hard carbonized fouling .

Now it would seem this would be ok as then we would have a natural Flue as was designed for the flintlock application . Well really you don’t as in some areas there will be pockets of larger air space behind the liner or at the corner of the 90 deg turn. This manifests itself as un reliable ignition in both the flintlock and cap lock applications . Less so for the cap lock do to the higher pressure and directed fire and heat from the cap .

As I alluded , this was an early topic here . I actually did some cut a ways of different breech plugs and photos of the pedersoli breech , the fix for that breech if it should become troublesome .

So first is a photo of a pedersoli breech plug from one of their flintlock rifles . This is what I often see when someone brings me one of their rifles that is having ignition issues

Note that we can see inside the Antechamber and that it appears to be open even though we do see fouling . Also , we can clearly see that this plug was not sealing and fouling was working its way down the threads

Now I don’t seem to have the photos of the liner that went with this plug or the corresponding photos of a drum breech from a rifle that suffered from the same issues . But here is a photo of the face of the breech . Note the fouling buildup and resulting small hole I spoke of .

This is how big the Antechamber should be , as produced by pedersoli

Now the Fix if you begin to have issues . Well as the others have said . Start by keeping it clean . Use the dowel or get a small 22 cal brush that you can use to scrub out this chamber during cleaning . Just twist it as you go into the chamber and keep twisting as you remove it .

If you end up reaching the point where you have to have the breech pulled , drill out the chamber alittle .

I normally ream them out to .250 and as of yet not had on returned for the same issue.