I have drilled a hole into the toe plate and a hole in the toe of the stock. I put inletting black on the bottom of the toe plate and screw it down. then tap on it all around with a hammer handle.

I am now cutting a line all the way around the inside of the inlay with a V tool.

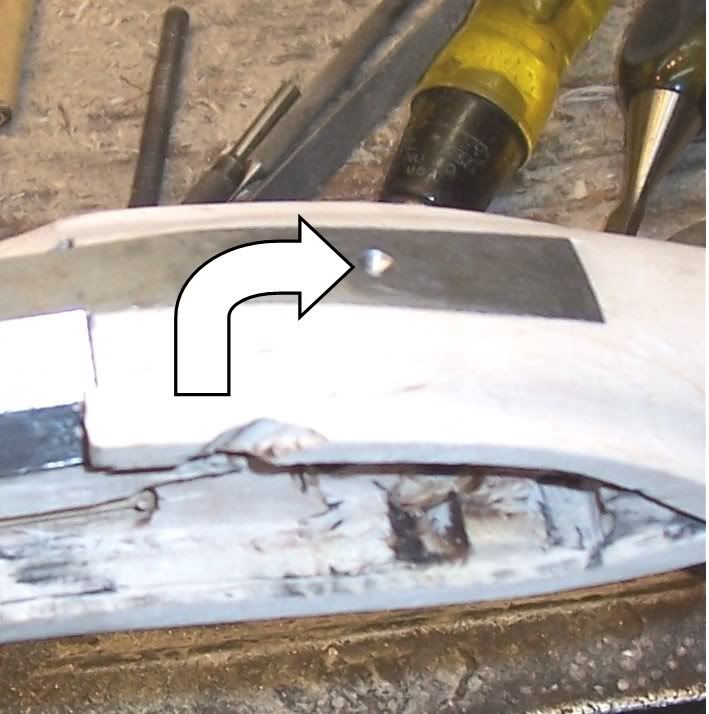

Here you see the V trench finished. I then take small chisels and gouges and cut straight down around the black print made by the blackened inlay. The wood gives way, but it collapses into the V trench, so the mortise for the inlay doesn't get too big.

The toe plate is inlet 100%, and sanded smooth. The whole toe line of the stock is then sanded to 400 grit.

On this rifle I am using double set triggers (a deviation from the real Lehigh county style, but it's what the customer wanted). I strip the triggers down and lay the trigger plate on the center line of the stock, and align the set screw hole with the lock's sear bar. I trace a line around the trigger bar with a pencil. I have a hole for a wood screw in the rear of the bar. I use the V tool to trench around the inside of the line I just drew. I then blacken the underside of the bar, and screw it down in it's proper position. I tap around it and then remove the screw. As you can see, it leaves me sharp lines where it will need to be inlet

I have the bar inlet completely. I drill a simple divot where I want my tang screw to come out.

I am using a 10x32 bolt, so I use a number 22 drill here. That's the root size for a 10x32.

I drill a similar divot where I want my tang bolt to go in.

Here's a cool trick. I have a screw adjustable vice, but all you really need is a piece of wood with a short nail pounded through it and a drill press. You will move the nail around until it's point to point with the drill in your chuck.

Here I have run the drill bit down so you can see what I mean. It's point to point with the nail.

I set the nail into the divot I made in the trigger bar. The drill bit is still aligned with it. I move the rifle until the drill bit is in the divot I made in the tang. now I drill halfway through. You go halfway, and then reverse the rifle and come from the other side. The minimizes any "run-out" of the bit.

(if you don't have a drill press, you will have to just try to get things aligned by eye, and by feel. Have someone help you by viewing the angle of your drill from 90 degrees off from where you are viewing it, and try to get things aligned as well as you can)

Here I have moved the rifle back to my bench, and I drill a clearance hole through the tang and the wood. In this case, I use a number 9 drill.

Now I tap my hole.

Here you see the tap coming out. The alignment is perfect if you do it this way.

I now counter sink the screw hole. Screw in your tang bolt and cut it off to the correct length from the other side.